Lean Six Sigma

Export Control & Tariff

EASA Part 21 and 145 Release

Experience

– Green Belt Six Sigma

– FRACAS (Failure Reporting, Analysis and Corrective Action System)

– Flight Safety

– Project Management

– Technical Support for Manufacturing and Customer Services

– Air Publications including Service Bulletins, Component Maintenance Manuals.

– Project Management of Design Changes

– Customer / Airworthiness Approval.

– Engineering Approval / Sign-off

– Executive Level (High level) Presentations & Technical Presentation Skills

– Quality System: Corrective Actions / Non conformances, ISO

– Interviews

– Tagging & Tariff trained for Import & Export Control

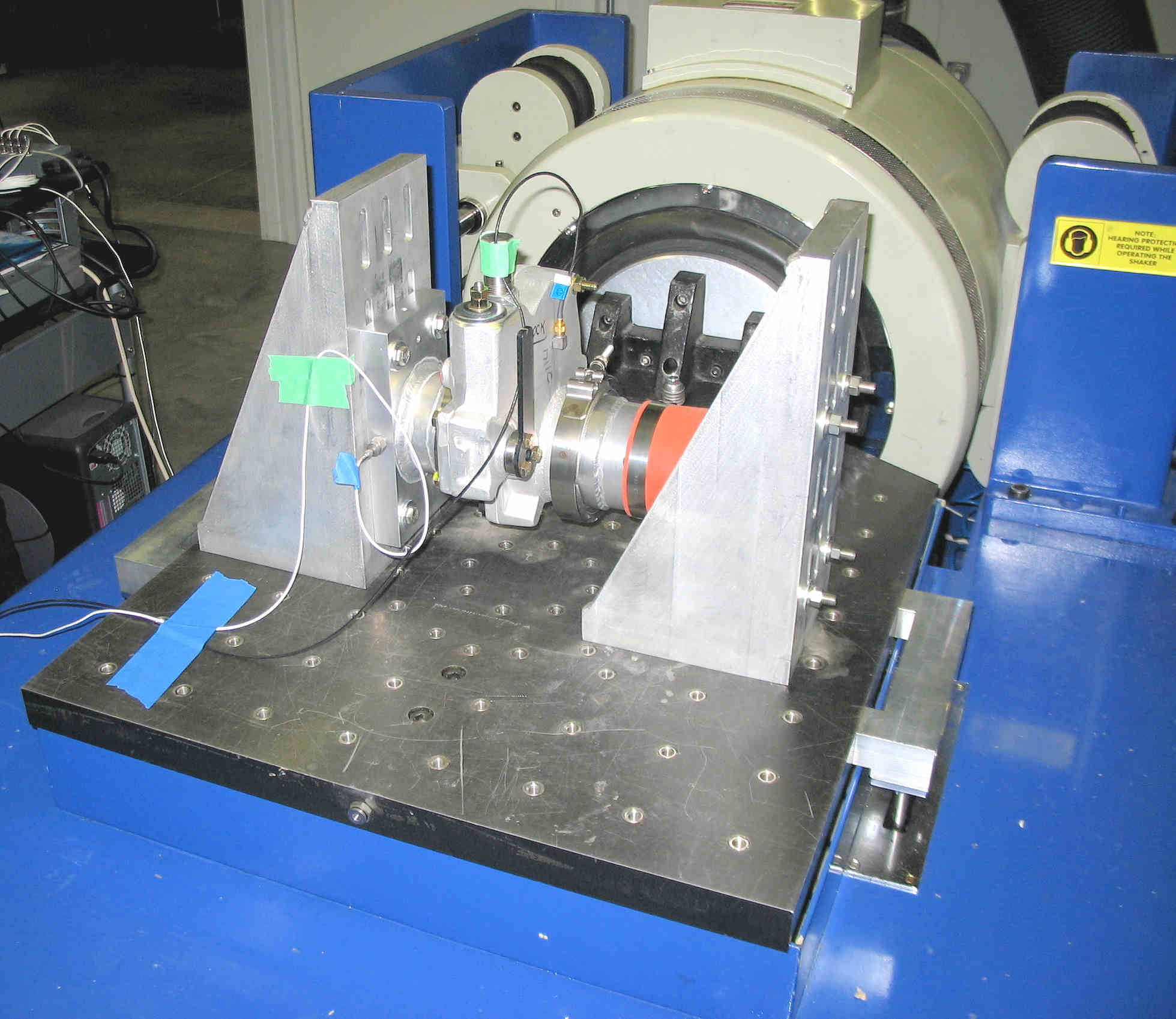

Environmental Stress Screening

During my role as Electronic Engineer for British Army defence project WAH-64D Apache Longbow Attack Helicopter, I was responsible for sub-assembly and system level testing on range of electric and optical equipment (TADS/PNVS).

Performed Environmental Stress Screening (Thermal, Vibration)

Performed root cause analysis down to component level.

Developed tools to improve the manufacturing cell and wrote engineering test documentation.

Obsolescence Management

Technical sign off for Form Fit Function replacement components.

This includes electronic integrated circuits, passive and active components on a range of equipment including fuels, landing gear, Power systems & Avionics.

In-Circuit Testing

Experience tester on GenRad 121 bed of nails tester for printed circuit boards, harnesses, and populated circuit card assemblies. Fault diagnosis down to component level using circuit diagrams, and general engineering tools such as oscilloscope and DMM.

Responsibilities

– In-Service FRACAS (Failure Reporting, Analysis and Corrective Action System)

– Flight Safety Technical Support.

– Project Management of Major In-Service Problems

– Technical Support for Customer Services and Manufacturing.

– Verify Air Publication such as Service Bulletins, Component Maintenance Manuals.

– Project Management of Design Solutions from Cradle to Grave. Obtain Customer / Airworthiness Approval.

– Present Executive Level Failure Review Boards.

– Present Product Scorecards to Avionics Leadership.

– Improve Customer Satisfaction.

– Export Control Tagger.